Vertikale Mini-Desktop-Kantenpoliermaschine.

STABILE MATERIALLAGERUNG

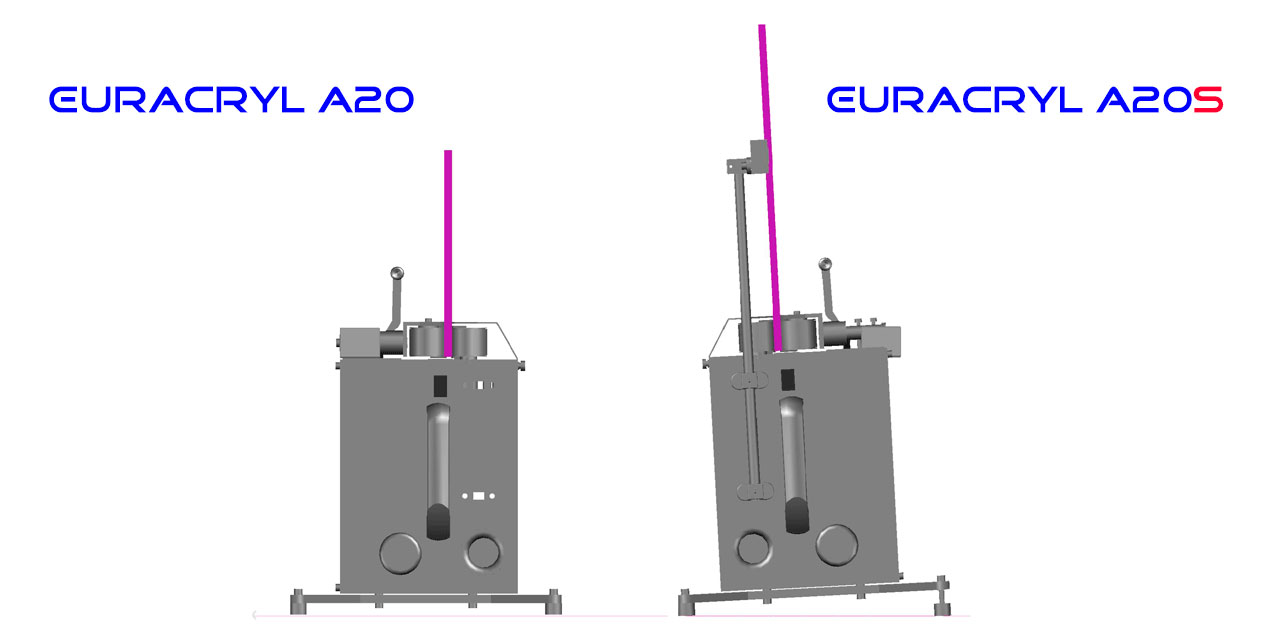

Das Modell EURACRYL A20 ist für kleinere

Materialformate konzipiert. Das Modell EURACRYL

A20 S mit Materialauflage eignet sich besonders für die

gelegentliche Bearbeitung von Werkstücken mit

größeren Formaten.

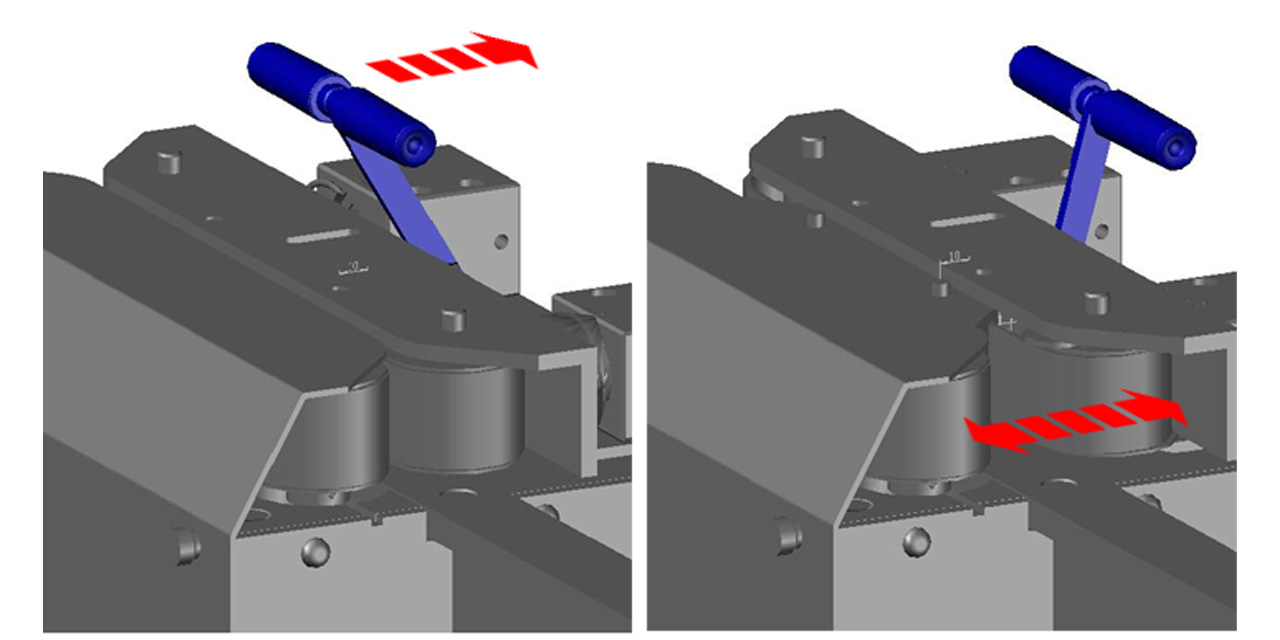

EINSTELLUNG DER MATERIALSTÄRKE

Die Materialstärke kann von 2 bis 20 mm gewählt

werden und wird bequem und ohne Kraftaufwand

durch Drücken des Spannhebels eingestellt.

MOBILER EINSATZ

Die Maschine ist kompakt und leicht gebaut,

so dass der Einsatzort schnell geändert

werden kann. Sie ist jedoch robust genug,

um jederzeit ein optimales Finish der Werkstücke zu gewährleisten.

MASCHINENGEHÄUSE

Die kompakte Bauweise der Maschine ist nur dank eines sehr kompakten elektrischen Konzepts möglich. Um eine Überhitzung der Maschine zu vermeiden, besteht das gesamte Maschinengehäuse aus wärmeableitendem Aluminium mit zusätzlichen Lüftungsschlitzen.

FRÄS-/POLIERWERKZEUGE

Eine Auswahl aus 22 Standard-Werkzeugen ermöglicht die

Bearbeitung von Kunststoffen (PMMA, PC, PET-G, SAN etc.)

oder Verbundwerkstoffen (PMMA mit Aluminium oder Papier),

sowie die Herstellung von hochglänzenden, glänzenden oder

satinierten Oberflächen. Mit den Werkzeugen des Typs HIGH

SPEED können Sie die Vorschubgeschwindigkeit auf bis zu 200% erhöhen.

TECHNISCHE DATEN

| Materialstärke (mm) | 2 … 20 |

| Materialänge / mit Zubehör (mm) | 50 … 800 / … 1200 |

| Fräsmotor-Leistung (kW) | 0,8 |

| Antriebsmotor-Leistung (kW) | 0,3 |

| Gewicht (kg) | 22 |

| Vorschubgeschwindigkeit (m/min) | 0,1 … 5,0 |

| Motordrehzahl (1/min) | 0 … 18.000 |

| Frästiefe (mm) | ~0,5 |

| Elek. Anschluss (V/Hz) | 230 V / 50-60 Hz |

| Anschlußdurchmesser Spanabsaugung (mm) | 32 |

| Gesamtleistung (kW) | 1,1 |

| Werkzeug enthalten / Anzahl der Schneiden | Hochglanz / 2 |